- MACH3 CNC FULL CRACK HOW TO

- MACH3 CNC FULL CRACK FULL VERSION

- MACH3 CNC FULL CRACK FULL CRACK

- MACH3 CNC FULL CRACK DRIVERS

- MACH3 CNC FULL CRACK SOFTWARE

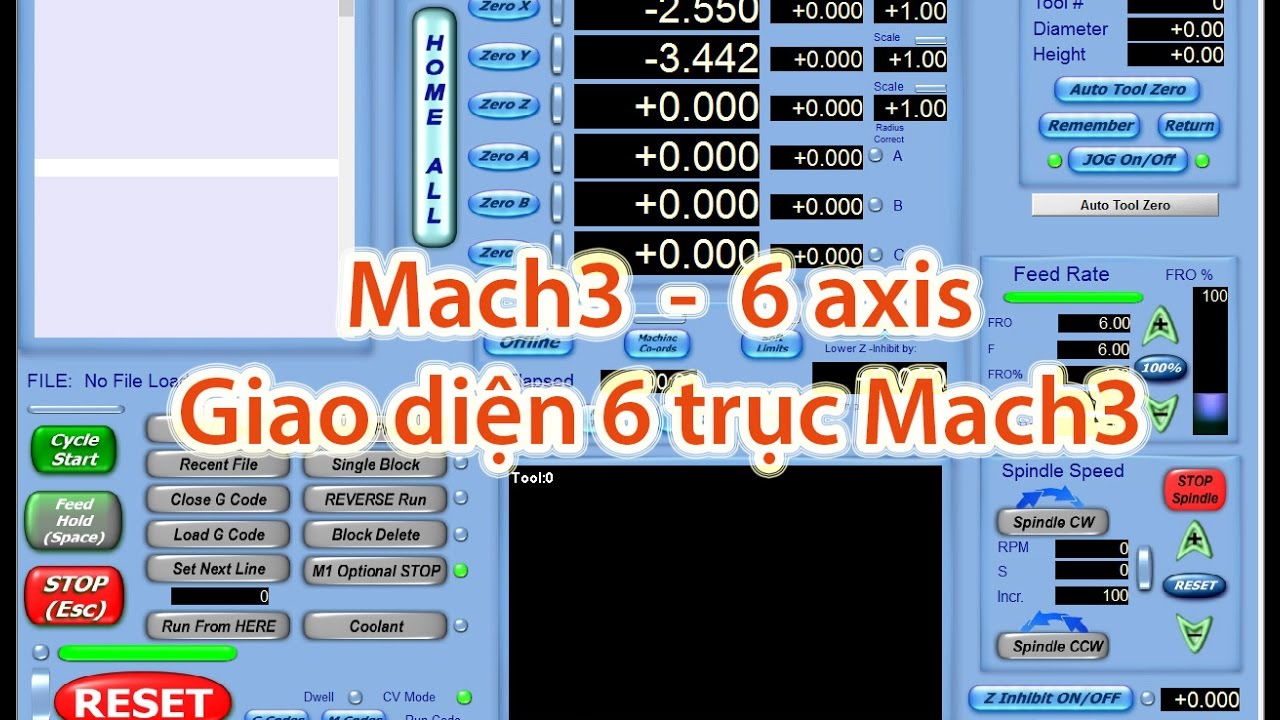

– Improved screen layout and easily customizable screen modification tool.Ĭhange buttons, displays, and indicators easily, quickly, and on the fly! View, rotate, pan, and scale the tool path quickly and easily to ensure G-code is creating the path you expect. Link information between other computer applications – Multi-Axis Work Shifts and Head shifts to offset cutting tool path for multiple work piece holders and fixtures.- Remote Control of machinery (IPC)Ĭontrol or track CNC equipment from a remote location

MACH3 CNC FULL CRACK FULL CRACK

– Asynchronous Motion (out of band axis) to control uncoordinated motion.ĭownload Mach3 Full Crack DownloadTorch height manual compensation control Multiple heads, machines and processes to produce complex parts. – Synchronous Motion of up to 6 completely separate coordinate systems (instances) at the same time. More accurate tool path compensation for different size tools – Type C (Fanuc) cutter compensation standard in Mach4. – Improved Backlash Control & more accurate screw mapping = less jitter and more accurate cuts Machine hold or speed changes happen as quickly as GUI buttons are selected on the screen. – Up to 100x faster response from button click to machine action.

MACH3 CNC FULL CRACK SOFTWARE

Mach3 software relied on the hardware plug-in software and complex buffering schemes to ensure accuracy and coordinated motion. Mach4’s core adapts to the speed (frequency) of the motion controllers attached.

MACH3 CNC FULL CRACK DRIVERS

– Motion Device Drivers (Plug Ins) have standard format = common level of functionality between components, less complexity, easier and less costly to troubleshoot and support.Īll motion control calculations are completed in the core. – All Motion control calculated in the core = less dependence on hardware and associated software driver. The core is a full featured ‘brain’ that ensures all input and output devices are coordinated with motion. Mach4 can control CNC machinery, PLC equipment, and robotics. While we are controlling other machine types with our Industrial software, complete hobby solutions with integrated screens and functions have only been completed for these machine types. The standard Mach4 installer will control mills, drills, lathes, and routers. Mach4 has been in use on Industrial equipment running constantly for over a year. While there was only one version of Mach3, Mach4 is offered in different versions. When quality, speed, and the ability to use or learn industrial style controls and methods are what is needed, Mach4 is the correct choice.

Mach3 was designed for simple hobby machines and still serves this purpose well. It was written from the ground up to be expandable, flexible, and extremely responsive for use with very large files. Mach4 is completely new software with less than 1% of the programming code in common with Mach3. And many more programs are available for instant and free download. Photo & Graphics tools downloads - Mach3 by ArtSoft CNC Software Inc. Mach4 is our newest version of CNC motion control software.

MACH3 CNC FULL CRACK FULL VERSION

MACH3 CNC FULL CRACK HOW TO

If you look at the manuals for MACH3 they are huge and very detailed with many examples on how to hook up things write custom code, etc. Re: Mach 3 VS Mach 4 Probably my biggest complaint about MACH4 is the lack of documentation.

0 kommentar(er)

0 kommentar(er)